Longer-lasting batteries and lighter-weight vehicles. Wireless charging stations and sustainable materials. More efficient supply chains and more effective public policy.

UT researchers are at the forefront of the technology and societal forces that are revolutionizing transportation here in the United States and around the world.

By bringing together the university’s deep bench of expertise, the state’s robust manufacturing ecosystem, and the real-world experience of industry and other partners, UT has positioned itself as a leader in the future of mobility.

“We are at the cusp of a new era in how we move people and goods from one place to another, and that is creating opportunities to be part of the new mobility economy,” said Deborah Crawford, UT’s vice chancellor for research, innovation, and economic development. “Our strengths in fields like advanced materials and manufacturing, artificial intelligence, and supply chain management, combined with our mission as a flagship land-grant university, make UT an ideal partner in not just developing critical research but also training the future workforce and crafting the public policies we need.”

The future of mobility includes the technology shaping the next generation of vehicles—like electric charging and autonomous cars—along with the ways people and communities use transportation. That, too, is shifting with the evolution of ride-sharing services, remote work, and public infrastructure.

The future of mobility includes the technology shaping the next generation of vehicles—like electric charging and autonomous cars—along with the ways people and communities use transportation. That, too, is shifting with the evolution of ride-sharing services, remote work, and public infrastructure.

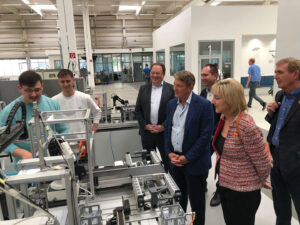

Approaching future mobility with a wider lens means bringing together experts from across disciplines and organizations. Partnerships with industry, government, and other colleges and universities are critical to success.

The race among states is on to attract the next generation of automotive employers and investors in electric vehicle research and development and to leverage advances in automation to better serve individuals, communities, and organizations. In Tennessee there are currently more than 900 companies in the automotive manufacturing sector that employ about 140,000 workers.

UT is in a unique position to bring together world-class research, workforce development, community engagement, and partnerships with industry,” said Kevin Heaslip, director of UT’s Center for Transportation Research and head of the new Institute for Future Mobility. “Our faculty and students are solving real-world industry problems and meeting real people’s needs. We’re steadily deepening the world’s understanding of the science behind better mobility and commercializing new technologies to help make it safer, cleaner, and more efficient and affordable.”

The Institute for Future Mobility, which launched in September, connects industry and community partners with UT researchers representing engineering, computer science, agriculture, chemistry, social work, economics, public policy, supply chain management, and other fields. It also builds on multi-university national initiatives that reach beyond UT, such as the US Department of Transportation–funded Center for Freight Transportation for Efficient and Resilient Supply Chain and TEAM TN, a first-of-its-kind statewide mobility coalition funded by the National Science Foundation.

TEAM TN is a coalition of more than 100 organizations, led by UT and representing industry, community, economic development, and higher education organizations including technical and community colleges as well as four-year universities. TEAM TN will develop and commercialize new technologies, attract new businesses and research investments to the state, and prepare Tennesseans for well-paying jobs in the mobility sector. This initiative aims to put the entire state of Tennessee at the cutting edge of the mobility revolution and win a larger share of the future mobility market, estimated to reach $2 trillion by 2030.

Initiatives like the Institute for Future Mobility and TEAM TN are fueling the university’s research and its visibility, leading more partners to turn to UT experts for help addressing challenges.

UT’s mobility research advances solutions in three primary areas: decarbonization, digitization, and societal mobility. By approaching their research with an eye toward industry and the research needs of the university’s partners, UT’s faculty and graduate students are able to tailor their work to meet the challenges that matter most in the real world.

“This is how we create the most meaningful impact—locally and globally,” Heaslip says.

Decarbonization: Creating a Clean and Powerful Future

The transportation sector is one of the largest contributors to greenhouse gas emissions in the country, and tailpipe emission pollutants directly affect human health. Investors, companies, and consumers alike are seeking sustainable transportation options.

UT researchers see immense potential to create positive change by developing low-carbon alternatives to fossil fuels and driving the shift to zero-emission electric motors. Ultimately, the goal for alternative fuels and electrification is to create cost-competitive solutions that shrink transportation’s environmental footprint while simultaneously improving vehicle performance and the experience of the consumer.

UT research focuses not only on personal vehicles but also on heavyduty trucks, trains, ships, and planes. It spans hydrogen fuel cells and hydrogen combustion, biofuels derived from wood and fast-growing nonwoody plants, batteries, and the power electronics that are essential to modern vehicles.

Fuel and electrification research go hand in hand: alternative fuels are a bridge to the eventual large-scale shift to electrification, and they will continue to provide viable options for some modes of transportation far into the future. High-performance fuel cells, for example, currently show more promise than batteries for sustainable long-haul trucking. UT participates in the US Department of Energy’s Million Mile Fuel Cell Truck Consortium to increase fuel cell durability, providing a longer-lasting energy source and lower cost of ownership for owner-drivers.

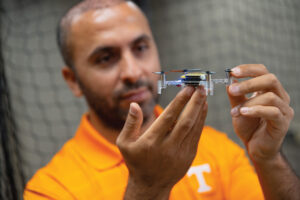

When it comes to electrification, UT faculty are advancing technologies that make EVs more attractive to more users. They’re helping increase battery range, improve the convenience of charging, and decrease users’ overall energy consumption over time. Electric power and propulsion for automobiles and aircraft require several types of technology, including chargers, batteries, electric motors, and power converters, among others.

Digitization: Improving Vehicle Connection and Computation

Today’s new cars already use some automated features, like adaptive cruise control and lane assist. Progress in fully automating vehicles—making them self-driving—continues to accelerate.

UT faculty and students are developing communications and computational technologies to enable connected automated vehicles to observe the world through cameras, sensors, and GPS; share real-time information with other vehicles; communicate with smart infrastructure like traffic lights and pedestrian walkways; and take effective actions in response to real-time data.

Researchers envision a future their work is helping to shape: people in and around vehicles will be safer, traffic jams will be a problem of the past, vehicles will run more efficiently, and goods will be shipped more efficiently.

Researchers envision a future their work is helping to shape: people in and around vehicles will be safer, traffic jams will be a problem of the past, vehicles will run more efficiently, and goods will be shipped more efficiently. To bring this vision to life, multidisciplinary collaboration is essential. Experts in 5G+ wireless communication technology, cybersecurity, and machine learning, for example, build on one another’s work. Mechanical engineers partner with computer vision experts while relying on civil engineers to analyze traffic accident data. Together they’re making sure future vehicles can generate, analyze, and act on the right data—rapidly, reliably, and safely.

Assistant Professor Subhadeep Chakraborty from UT’s Tickle College of Engineering is advancing human safety in and around connected automated vehicles. “If you change one factor around the vehicle, what counts as safe or unsafe behavior changes,” he says. “So we are defining safety bounds for vehicles that are tuned to the level of the vehicle’s automation, the driver’s responses, and different weather and other environmental conditions.” Testing vehicle automation systems on the road can be both expensive and dangerous. Mechanical engineering PhD student Joe Beck and other members of Chakraborty’s group have developed an innovative testing process. Beck designs virtual simulations of various driving scenarios and feeds them into an actual car’s processing hardware. The vehicle responds as if it were receiving input from real cameras and sensors—accelerating, turning, and braking while safely lifted on rollers with a chassis dynamometer.

“We can change one factor at a time. I can have the same pedestrian walk in front of the car, but with the sun at different angles to see how the camera vision registers glare,” Chakraborty says. “It’s unique to have this kind of control, and it’s safe for everyone involved.”

Societal Mobility: Driving Opportunities

Mobility doesn’t happen in a vacuum. Infrastructure design and maintenance, transportation policies, economic incentives, human behaviors, socioeconomic factors, cultural trends, and climate change are all among the considerations that influence how well mobility works for different people.

UT researchers are studying how people and goods move today and pursuing ways to strengthen the systems and structures that can make better mobility possible in the future. Faculty engage in these topics from across the Baker School of Public Policy and Public Affairs, the College of Arts and Sciences, the College of Social Work, the Haslam College of Business, the Tickle College of Engineering, and the UT Institute of Agriculture. Their investigations cover urban, suburban, and rural areas.

Some researchers focus on micromobility, public transit, and equitable transportation access. They examine human behaviors and the impacts of new technologies and policies. UT economists and engineers frequently advise national and state government agencies in developing transportation policies, understanding policy impacts, and financing infrastructure priorities.

Other researchers focus on improving the freight transportation that keeps America’s economy rolling. US annual freight volume is expected to double in value between 2020 and 2050. At the same time, drivers are retiring and not being replaced. More frequent extreme weather events disrupt supply chains. And freight accounts for almost 10 percent of US greenhouse gas emissions. UT is tackling challenges from many angles through the Transportation and Logistics Collaborative and the Center for Freight Transportation for Efficient and Resilient Supply Chain.

By addressing real-world problems for communities and corporations alike, faculty, staff, and students are helping remove barriers to and create new opportunities for personal well-being, economic opportunity, and environmental sustainability.

“When our students graduate, they already understand their future employer’s biggest problems and the cutting-edge solutions to those problems. They’re ready to make their mark on the company they choose.”

Prepared for Life

Through all this research, both graduate and undergraduate students are involved in asking questions, engaging partners, and developing new technologies. They have access to state-of-the-art facilities on and off UT’s campus, and they learn from world-class researchers not only at UT but also at Oak Ridge National Laboratory and other partner organizations. As faculty members point out, government and industry partners bring their real-world problems to solve—giving students opportunities to build skills and experience and, most importantly, to help develop real-world solutions.

“When our students graduate, they already understand their future employer’s biggest problems and the cutting-edge solutions to those problems,” Heaslip says. “They’re ready to make their mark on the company they choose.”

“I believe the real-world impact of my research will be clear in the very near future,” says Beck. “Car manufacturers need a cost-effective platform to develop [self-driving] systems. But perhaps more importantly, regulators will need platforms for validation. Using vehicle simulation platforms to both discover common failure scenarios and validate against them will be critical for public trust and safety as vehicle automation continues to expand.”

“I give students like Beck the overview and goal,” says Chakraborty, who serves as Beck’s advisor. “Then they do so much with that! These students are preparing to lead any organization in the world.” The Office of Undergraduate Research and Fellowships, part of UT’s Division of Student Success, helps undergraduates get involved through internships, co-ops, and experiential learning. Graduate students pursue research opportunities through traditional graduate research assistantships and other programs. For example, graduate student fellowships are a key element of UT’s partnership with Volkswagen Group of America Inc. Whether the students plan to remain in academia or enter industry, they jump-start their careers as they tackle a wide range of scientific and business challenges. Since 2020, fellows have pursued a variety of research interests, including advancing fiber-reinforced plastics and new lower-carbon materials that are recyclable or reusable. Others have investigated how the shape of materials affect performance in a car crash and explored new technologies like EV wireless charging. Volkswagen plans to expand the number of fellowships offered to graduate students as well as undergraduate internships.

“I give students like Beck the overview and goal,” says Chakraborty, who serves as Beck’s advisor. “Then they do so much with that! These students are preparing to lead any organization in the world.” The Office of Undergraduate Research and Fellowships, part of UT’s Division of Student Success, helps undergraduates get involved through internships, co-ops, and experiential learning. Graduate students pursue research opportunities through traditional graduate research assistantships and other programs. For example, graduate student fellowships are a key element of UT’s partnership with Volkswagen Group of America Inc. Whether the students plan to remain in academia or enter industry, they jump-start their careers as they tackle a wide range of scientific and business challenges. Since 2020, fellows have pursued a variety of research interests, including advancing fiber-reinforced plastics and new lower-carbon materials that are recyclable or reusable. Others have investigated how the shape of materials affect performance in a car crash and explored new technologies like EV wireless charging. Volkswagen plans to expand the number of fellowships offered to graduate students as well as undergraduate internships.

Providing industry-informed hands-on experiences like these within the context of STEM undergraduate and graduate degree programs is critical for Tennessee’s long-term leadership in the mobility industry. Equally important are technical apprenticeships and programs that reskill and upskill Tennesseans for high-demand jobs. Workforce development objectives are embedded into many UT mobility research projects. Funded projects often encourage collaborations with local community colleges and workforce development organizations. Workforce development is one of the four core pillars of TEAM TN, for example.

Powering Progress and Benefits

“We’re at the right place, at the right time, with the right people and partners for UT to lead on future mobility,” says Heaslip. Students, workers, corporate partners, and neighbors in Knoxville all stand to benefit. “There’s something for everyone,” he adds. “Cleaner air. Better access to health care and jobs. Safer roads. Economic and workforce development. Tennessee becoming a richer innovation ecosystem.” UT research is powering progress in all of these directions.

1 comment

Would a heavy duty (Class 8) 80,000 LB. GVW truck, as compared to the most common 80,000 GCW Class 8 Combination Vehicles in use today, providing the specific benefits listed below, have a role in the University’s Idea of Future Mobility as described herein: 1) More efficient handling; 2) more cubic capacity; 3) safer to operate; 4) more effective adoption of autonomous systems; and 5) more effective design for the functionality of battery electric and/or hydrogen electric propulsion.

Comments are closed.